What kind of test is salt spray test ?

We all know that salt spray corrosion is a common and destructive atmospheric corrosion.

a product sample is tested in a natural exposure environment, it may take 1 year for it to corrode. The test under artificial

simulated salt spray environment conditions is a salt spray test. It only takes 24 hours to obtain similar results.

What is the purpose of salt spray testing?

Salt spray test is an important method to evaluate the resistance of metal products to salt spray corrosion. The salt spray test ir

the laboratory mainly uses a test chamber to simulate the actual application environment of the product in the laboratory to

evaluate the corrosion resistance of products and materials.

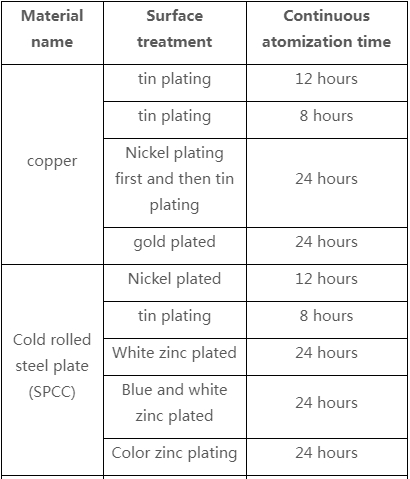

Salt spray test continuous fogging time

The schedule for continuous atomization of various types of material coatings is as follows:

Factors affecting salt spray test

1. Test temperature and humidity

The critical relative humidity for metal corrosion is approximately 70%. When the relative humidity reaches or exceeds this critical

humidity, the salt will deliquesce and form an electrolyte with good electrical conductivity. When the relative humidity decreases,

the concentration of the salt solution will increase until the crystallized salt precipitates, and the corrosion rate decreases

accordingly. As the temperature rises, the molecular movement intensifies, and the corrosion rate of high salt spray increases.

According to the International Electrotechnical Commission: for every 10°C increase in temperature, the corrosion rate increases

by 2 to 3 times, and the conductivity of the electrolyte increases by 10 to 20%. For the neutral salt spray test, it is generally

believed that the test temperature is 35°C.

2.Concentration of solution

When the concentration is below 5%, the corrosion rate of steel, nickel, and brass increases with the increase in concentration;

when the concentration is greater than 5%, the corrosion rate of these metals decreases with the increase in concentration. This is

because, in the low concentration range, the oxygen content increases with the increase of salt concentration; when the salt

concentration increases to 5%, the oxygen content reaches relative saturation. If the salt concentration continues to increase, the

oxygen content decreases accordingly. As the oxygen content decreases, the depolarization ability of oxygen also decreases, that

is, the corrosion effect is weakened. For metals such as zinc, cadmium, and copper, the corrosion rate always increases with the

increase in salt solution concentration.

3. Sample placement angle

The settling direction of salt spray is close to the vertical direction. When the sample is placed horizontally, its projected area is

the largest, and the surface of the sample bears the largest amount of salt spray, so the corrosion is serious.

4.PH value

The lower the pH value, the higher the concentration of hydrogen ions in the solution, and the more acidic and corrosive it is. The

pH value of the neutral salt solution is 6.5~7.2. Due to the influence of environmental factors, the pH value of the salt solution

will change. For this reason, domestic and foreign salt test standards have stipulated the pH range of salt solutions, and proposed

methods to stabilize the pH value of salt solutions during the test to improve the reproducibility of salt spray test results.

5. Salt spray deposition amount and spray method

The finer the salt spray particles, the larger the surface area formed, the more oxygen is adsorbed, and the more corrosive it is.

Traditional spray methods include air pressure spray method and spray tower method. The most obvious shortcomings are the

poor uniformity of salt spray deposition and the large diameter of salt spray particles. Different spray methods also have an

impact on the pH value of the salt solution.

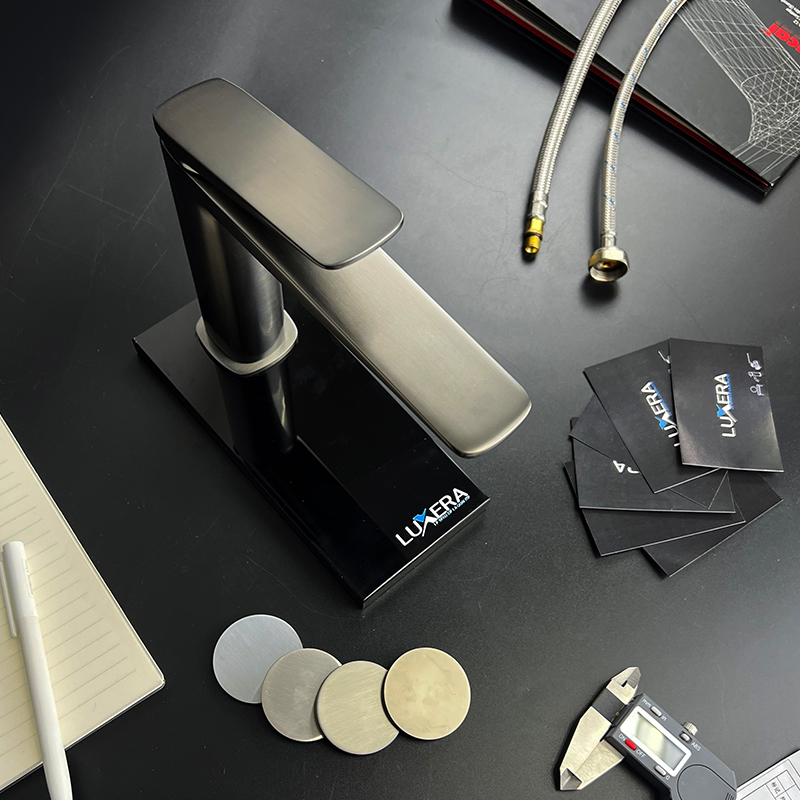

Faucets also need to be tested for salt spray during production. Because the faucet surface is chrome plated, the salt spray test is to test whether the corrosion of the batch coating meets the requirements. If the test does not meet the requirements, it means that the coating is too thin or the binding force is not good, and the coating is easy to fall off. This will make the faucet not beautiful, not durable, so to carry out sampling.